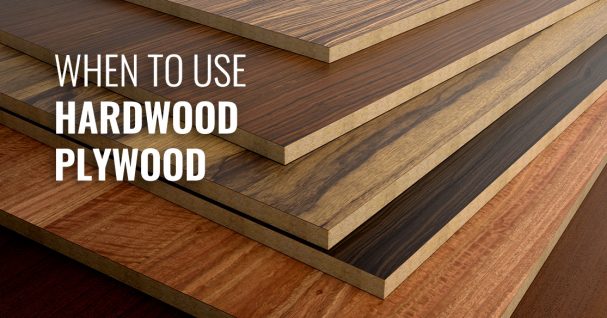

Hardwood plywood is manufactured by gluing together multiple layers of wood. The face and back veneer are made out of hardwood, which comes from deciduous trees like birch, oak, mahogany, maple, teak, and beech.

Depending on the manufacturer and type of plywood, the core can be made from any type of material, including softwood, hardwood, particleboard, or MDF (medium-density fiberboard).

Advantages Of Hardwood Plywood

Plywood is an inexpensive and green alternative to traditional solid wood and is available in many grains, species, and grades.

Known for its strength and durability, plywood is less likely to warp than softwood plywood. It is available in a variety of thicknesses and comes in large sheets, with the most common being 4- x 8-feet, followed by 5- x 5-feet.

Plywood that is available pre-sanded, ensuring a smooth and even surface, can be a time-saver. This type of plywood has a finished appearance, making it suitable for cabinets, furniture, and other projects visible to the eye.

Disadvantages Of Hardwood Plywood

Because of its thin veneers, plywood can be difficult to cut without splintering. Sanding must be done with care to ensure that it doesn’t sand through, exposing the core.

While plywood is less likely to warp than softwood, it is more likely to warp than solid wood. Delamination, which occurs when the layers of veneer held together with glue separate, can be another concern. Delamination can be caused by improper manufacturing, exposure to moisture, extreme heat, and pressure from nails and screws inserted close to the edge.

Best Uses for Hardwood Plywood

Common uses of plywood in residential construction include cabinetry, furniture, decks, and support for walls, floors, and roofs. While plywood can be a money-saver, choosing the right type of plywood is mission critical.

Choosing the Right Hardwood Plywood

For furniture, cabinetry, and interior finishing that will be exposed to the eye, the quality and thickness of the face veneer are key. Although many woodworkers swear by veneer core hardwood plywood for its structural strength and stability, composite cores such as particleboard and MDF are preferred for professional cabinetmaking because they produce a smoother face, vary less in thickness, and are less likely to warp.

The Architectural Woodwork Institute Quality Standards recommend that veneer core panels be used only when they can be housed in areas where warping due to heat or moisture is not a significant issue.

If you are using plywood for projects that are load-bearing or will be exposed to the elements, look for plywood with more layers (or “ply”), which creates a thicker, stronger board.

Types of Hardwood Plywood by Ply Count

- 3-ply: is one of the most common types of plywood and is generally used indoors.

- 5-ply: is used indoors or outdoors, but is not suitable for framing permanent structures such as a shed or a home.

- Multi-ply: plywood has seven or more plies. This plywood is strong and durable enough for use in roofing, framing, and other outdoor projects.

Get High-Quality Hardwood Plywood Today

Plywood is a strong, economical building material. Let Forest Plywood help you choose the right type of plywood for your needs. With a wide selection of hardwood plywood and expert woodworkers, we’ll ensure your project stands the test of time.

Contact us today, or browse our hardwood plywood selection now.